A variation of the Wimshurst machine

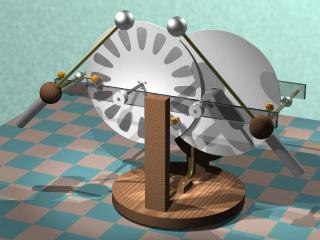

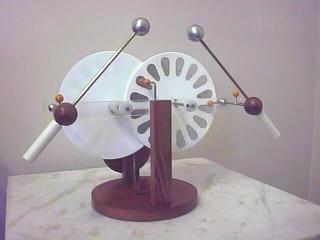

By February 2001 I imagined this curious machine, and built a prototype to see how it behaves. The machine uses the same charge generation principle of the regular Wimshurst machine, where two sectored disks pass one parallel to the other in opposite directions, touching "neutralizer" brushes (schematic). In the regular machine, this happens at the top and bottom quadrants of the disks. In this machine, both disks turn in the same direction on separate parallel axles, with an overlap at the center of the machine, and there two neutralizer brushes touch the sectors, building a single charge generation system. Opposite charges are collected from the sectors at both sides by sets of points or brushes, that are connected to the discharge terminals. I named it the "half Wimshurst machine".

The structure has also some relation to the Carré machine, that uses a friction machine to produce charges by induction an a rotating disk, and collects the charges at the other extremity of the disk. In this machine both disks serve as inductors, and the output is symmetrical, but an asymmetrical version is also possible, with one small disk turning slowly and a large disk turning fast. The fundamental differences are that the replenishing of the charges on the inductor disk would be done by influence, not by friction, and that the disks would have metallic sectors.

Construction:

I

made the machine quite small, with disks with 17 cm of diameter

made from white acrylic plate, 2 mm thick. Each disk has 16

sectors made of adhesive aluminum foil. The disks are fixed by

three screws to nylon cylinders with 2 cm of diameter, that are

fixed by set screws to 3/16" steel axles. The axles turn on

nylon supports inserted in two bars of transparent acrylic, and

are fixed in place by nylon rings with set screws at the frontal

side and by nylon pulleys at the back side. The bars are screwed

to two upright supports made of wood, that are screwed to a round

wood base. A wood pulley with nylon center, with a crank, is

mounted on a steel axle at the back of the machine. It drives the

upper pulleys through a round rubber cord. The driving pulley is

also fixed in place by a nylon ring with a set screw. Brass

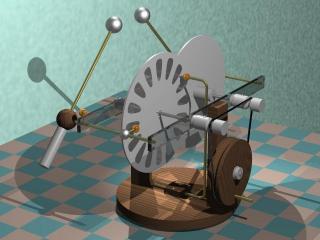

washers and some grease minimize friction at the five bearings. Back view of the machine.

I

made the machine quite small, with disks with 17 cm of diameter

made from white acrylic plate, 2 mm thick. Each disk has 16

sectors made of adhesive aluminum foil. The disks are fixed by

three screws to nylon cylinders with 2 cm of diameter, that are

fixed by set screws to 3/16" steel axles. The axles turn on

nylon supports inserted in two bars of transparent acrylic, and

are fixed in place by nylon rings with set screws at the frontal

side and by nylon pulleys at the back side. The bars are screwed

to two upright supports made of wood, that are screwed to a round

wood base. A wood pulley with nylon center, with a crank, is

mounted on a steel axle at the back of the machine. It drives the

upper pulleys through a round rubber cord. The driving pulley is

also fixed in place by a nylon ring with a set screw. Brass

washers and some grease minimize friction at the five bearings. Back view of the machine.

The neutralizer is a brass bar fixed to the base by a wood block with two screws, and ending in brushes made with nickel-chrome wires, fixed to the bars by plastic beads. The frontal neutralizer brush touches the frontal disk below the center, and the back neutralizer touches the back disk above the center. Seen from the back side, the disks turn clockwise. Side view.

The charge collectors are brushes of nickel-chrome wire held by plastic beads, that connect through short brass bars to aluminum balls that can slide over the lateral conductors, being fixed in place by set screws inside holes on them. The lateral conductors are 3/16" brass bars, that at the back of the machine are inserted in partial holes on the back acrylic bar, and at the front side cross the frontal bar, being fixed in place by screws with heads covered by plastic beads. The discharge terminals are made of 3/16" brass bars with threaded holes at one end, that receive aluminum balls made by metal spinning. At the lower side, they cross wood balls and end on nylon rings that support handles made of polished 1.5 cm PVC tubes. the wood balls have brass tubes inserted on them, that rotate over the lateral conductors, that end in slotted plugs inserted in the tubes. The tubes also make metallic contact with the terminal bars crossing the balls. Top view

The woods used were Riga pine for the base, uprights and driving pulley, and Peroba for the balls. All recycled from old boards and beams replaced in repairs in my house. The acrylic parts were made from discarded advertising panels and displays. The other materials were new.

Performance:

I was expecting something strange, as the disks operate with asymmetrical charge distribution at the sectors. And really, the machine works, but reverts polarity after each few tens of turns of the disks, being so an "AC" electrostatic machine. A different kind of AC machine, since it doesn't have fixed plates anywhere, as all the classic machines had [26]. It keeps the alternating operation in any condition, with or without sparks crossing the output circuit. Otherwise it is quite powerful for the size of the disks, producing sparks with up to 5 cm or more and about 8 µA of maximum output current. This is the same current expected for a regular Wimshurst machine with these disks, but the spark length is higher. Unfortunately, the longest sparks can be obtained only without the attachment of Leyden jars to the terminals, because the frequent alternations don't leave time for the charge of the jars to the maximum output voltage. Jars with very small capacitance can be charged, but they don't produce strong sparks.

The frequency of the reversals is affected by the presence or not of sparks at the output, with more frequent reversals occurring when the terminals are not sparking. At a given condition the frequency is proportional to the rotation speed. The separation of the disks also affects the reversal frequency, with larger separation decreasing the frequency. With small sparks at the output and wide separation it's sometimes (depends on the ambient humidity) possible to keep the same polarity almost indefinitely.

The machine works without reversals if just one disk is turned, the other being kept stopped, but charged. This can be obtained by attaching only one disk to the driving pulley, through a shorter cord, and turning the other disk for a few turns, just to get it charged. After this, the machine works for some time, producing unipolar output from the charge collector connected to the rotating disk. When the charge in the fixed disk weakens, reducing the induction effect in the rotating disk, a few turns replenish its charge, maybe then with a reversal. The machine works as a sectored Bertsch machine [p15] in this condition, with a curious method for the replenishing of the inductor charge.

Created: 26/03/2001

Last update: 04/10/2001

Developed and maintained by Antonio Carlos M.

de Queiroz

Return to Electrostatic Machines