I started experimenting with these machines by

1973, building a first series of machines. With this I learned a lot

about electricity, and I still think that all people interested in

electricity or electronics shall try these machines to get a real

feel of the subject. At least, high voltage static electricity is

something that you can see and feel. Eventually I abandoned the

subject for several years, but in 1996 I renewed my interest in this

subject, started to study and build new machines, and set up these

pages.

Below are pictures and descriptions of my old

machines, of machines that I built more recently, of machines built

by others, pictures from old books and papers related to

electrostatic machines and other high-voltage devices, and also some

pictures from museums. There are also extensive references, covering

classical and new materials. This site is always in construction. I

plan to add more details about the machines depicted and historical

material, as soon as I find or receive more data from interested

people, build and experiment with new machines, and have time.

To navigate through this site efficiently, use the

"open link in a new window" function of your browser to see

the pictures in the links, and use its search function for searching.

Recent changes.

A Wimshurst

machine [1][2] that I built in 1974. Front

view, back view, and with two Leyden

jars. A schematic diagram, with the disks

represented as cylinders, and a description of how

the Wimshurst machine works.

A Ramsden

friction machine [2], built in 1975. Small (18 cm acrylic disk),

but useful to test the insulation of materials and for for starting

the influence machines in humid days.

A Lebiez

machine, or simplified Voss machine [p31], in front

view and in back view. Built in 1975 as a

kind of Voss machine, and rebuilt in 1996 in this form. Schematic

diagram, with cylinders instead of disks for my machine. This

machine is equivalent to Lord Kelvin's "replenisher" (see

below), with better insulation. The classic Voss machine, also known

as Toepler-Holtz machine, is better and is built in this

way, with charge collectors and inductor plates separated. A

possible similar true Voss machine is shown here

and here.

A small cylindric

simplified Voss machine built in 1997, with the same

structure of the previous machine. Side

view, and another view. It is similar to a

Dirod machine [10].

A symmetrical 2

disks Toepler machine [4], with some modifications, built in

1997. Side view, another

view. A drawing. A schematic

diagram, with the disks shown as cylinders. This machine has

excellent performance, and can generate higher voltage and even more

current than a conventional Wimshurst machine with the same disk

size. In 1999, I built a larger machine.

Look at the bottom of the page here for a

description.

The first classic Toepler

machine (1865) was built in this way

[4][9], with a different interconnection and disks with two sectors

only. Toepler described also a symmetrical

machine (1866) that is very similar to my machine (the picture

shows a sectorless machine and a similar device used as voltage

multiplier). schematic diagram [p39].

My first

sectorless Wimshurst machine, or Bonetti

machine [4][5][8] (ray-tracing drawing), built in 1997, with

31 cm disks. A drawing. Another

view. Pictures of the actual machine, in front

view, and back view. A detail of the

charge collectors and neutralizers.

Pictures (video frames) of sparks from this machine: A short

spark, a long spark with a loop, and a

longer one. The original

Bonetti machine (1894) [31] used series of brushes as

neutralizers instead of combs.

A Holtz

machine [2][4]-[7] of the first kind, that I built in 1997.

A drawing. Another

view, and a schematic diagram. Pictures

of the actual machine, in front view, and

back view. This machine was the first

really powerful influence machine, invented in 1865, and was very

popular, even requiring external excitation to start. An apparently

complete actual machine is here. Some

additional pictures, from books by H. Pellat: A Holtz

machine [6] (the fixed disk is in a wrong position), a better

picture [7], a double Holtz machine

[6][7], and a machine with neutralizer and

friction starter [6][7]. And another

good picture [14]. This picture shows a

machine with a more modern structure [22]. A multiple

machine [24]. Here is a picture of the Holtz

machine of the second kind, that uses two counter-rotating

disks, as the Wimshurst and Bonetti machines. A drawing

of a possible machine.

The Leyser

machine (1873) [4][19], is variation of the Holtz machine

with the output taken at positions that would be under the inductor

plates in the regular machine, and the neutralizer bar where the

original output circuit would be. This is the schematic

diagram of the machine, with a cylinder

instead of the disk. This is a different

design due to Weinhold (1887), with wood inductors and no

insulating plate [19]. This diagram [19]

shows how it operates. Initial plans for a machine that I have built

are here, in front view and back

view. The version that actually worked was somewhat different.

A double

Voss machine, or double Toepler-Holtz machine, with

classical structure, built in 1998. A drawing,

and a photo of the machine. This is a good

self-exciting machine, invented in 1880. With 27 cm rotating disks,

it produces sparks with up to 10 cm and more than 50 uA of

short-circuit current.

A Bohnenberger

machine (1798)[4], that I built in 1998. A drawing,

and a picture of the machine. An ancient

machine of the "doubler" type, it is not a powerful

machine, but is very interesting. See more about "doublers"

in the section about influence machines below.

In June 1999 I

made experiments with a bipolar Van de

Graaff generator, (drawing) similar

to the original

machine, but smaller.

This is a

large Bonetti machine, that I started to build in

December 1999. The disks are old ebonite disks that come with the

Radiguet & Massiot Bonetti

machine that I recently restored. A drawing

of it. Front view, and back

view. Another view of it, and another.

Some sparks, that may reach 20 cm..

In April 2000 I

finished a Wimshurst triplex machine.

(drawing). It's a double Wimshurst

machine, using the close proximity between the central disks to

increase the output current, through greater induction and mutual

shielding. Pictures of the machine, in front

view, back view, and side

view. The machine produces a high current (100 uA with the 36.5

cm disks rotating at 16 turns per second, 4 times more than a single

Wimshurst machine with the same disks). With the original design, it

reached only 8-12 cm sparks, eventually

reaching 14 or 15 cm on dry days, because

with the rather small separation of the sectors it easily sparked

through them and the neutralizer bars. With half of the sectors

removed, it produces consistent 15 cm sparks.

By the same time,

I made also a working version of Bennet's

doubler, a curious simple influence machine.

In August 2000 I

made a version of Nicholson's

doubler, the first automatic influence machine (1788).

In January 2001 I

completed a double Wommelsdorf machine,

following closely the original design of

[p84] (1920), but with modern materials. Front

view, and back view. A collection of

parts. Partial assembly.

Assembling the neutralizer. Neutralizer and

other details assembled. Back

view. The machine, almost complete. Back.

The disks, and the switches.

The complete machine. back

view, side view, other

side, and another view, with only

painting missing. The machine works quite well (13.5 cm sparks, 100

uA current) for the two 28 cm disks.

In March 2001 I

made a curious AC electrostatic machine,

apparently new, that I named as "half

Wimshurst machine".

And by April 2001

I extended the same idea to a three-disks

machine, that I named as "unfolded

Wimshurst machine".

A Wehrsen

machine, completed in April 2002. It is a prototype for a

large Wehrsen machine (see below), that I started to build in August

2001. Some parts for it at the start of the

construction. Almost complete, by March

2002. Back view. Working,

it performs quite well, with 11 cm sparks

and 70 µA of short-circuit current.

An electrostatic

linear motor, completed in January 2002.

A large

Wehrsen machine, first tested by August 2003. Almost

complete by July 2003. Another view,

back view. Ray-tracing picture.

Just before the first test. First test.

The machine is still without its definitive rotating disk due to

construction and insulation difficulties.

This is a

Toepler-Dirod machine that I was building

by March 2004, still without spark terminals, and with

terminals. It's connected as the symmetrical Toepler

machine, but uses Dirod-type disks.

A drawing of the final machine. The

machine works, but is weak.

Bohnenberger's

Bennet's doubler. A curious little machine that I built in

April 2004.

Bohnenberger's

Nicholson's doubler. A version of Nicholson's doubler with

back-and-forth movement, built in May 2004. So far not so good as

the other doublers.

A rotating

Bennet's doubler, with a new construction using sectored

disks, built in 2006. Photo of the

machine. Another view.

Wilson's

machine, the oldest influence machine with symmetrical

output, in a reproduction made in 2007. A good and interesting

machine.

A Van

de Graaff generator with external belt. A big machine for

"hair rising" demonstrations, completed in 2007.

Bennet's

doubler with reciprocating levers. A new structure for

Bennet's doubler based on Wilson's machine, built in 2007.

An "electrostatic

orrery". A classical demonstration device, built in January

2009. It is quite heavy, but works. This

site shows some similar old devices. Video.

Henley

electrometers built in 2009. Classical instruments first

described in 1772. A video

of them operating with an electrophorus. Videos of experiments with

an electrophorus: 1,

2.

A

Wimshurst machine with insulated sectors, built in

2008-2009. This machine is highly insensitive to humidity.

See also the

comments about machines that I have restored, in the section about

influence machines below. Of special interest, the Ducretet

and Roger and Radiguet and

Massiot machines.

Electronic

version of Bennet's doubler. An electrostatic generator

suitable for electrostatic energy harvesting.

Pfaff

and Svanberg multiplier. A complicated multiplier with four

plates, described in 1846. Built in 2011.

Replenisher

machine. A simple symmetrical machine described by Lord

Kelvin in 1867. Built in 2011.

Experiments with

enclosed spinners and flames. In

2011.

The Gläser

machine, that for awhile is a cylindric Wimshurst machine.

Built in December 2011.

Some simple

high-voltage measurements.

Belli's

doubler, and comments about the machines developped by

Giuseppe Belli.

A bigger

Half Wimshurst machine, completed in January 2014.

Polarity

detectors. Simple electronic electroscopes. Completed in

April 2014.

Tubular electronic

doubler of electricity, made in January 2015.

Double

electrophorus machine, made in April 2015.

Electronic

version of Wilson's machine, made in May 2015.

3D-printed

electronic electrostatic machines, starting in 2015.

A big Wimshurst

machine built by Jim Banas.

A sectorless

Wimshurst machine with 60 cm disks. This machine was built by Ed

Wingate. A spark from this machine. Another

sectorless Wimshurst machine, with 30 cm

disks. Similar to the one described by R. A. Ford in [8]. A more

recent picture. Side

and base view. Neutralizers, Charge

collectors. Another view. This machine

was built by J.

Hardesty and Ed

Wingate. Photos sent by Steve

Cole.

An old Wimshurst

machine repaired by Johannes Zolk in 1996, with the original broken

disks replaced by LP records, with good results. Front

view, and back view. Photos sent by J. Zolk.

A "shake-sphere"

machine [10], built by Joachim

Bolz and his students in 1997. It is an influence machine using

two balls in a tube, moved by shaking the tube, instead of disks. It

works as my Toepler machine above. An

schematic diagram of it. Photo and

drawing by J. Bolz. Operation of the

machine.

Complete plans for

a beautiful Wimshurst machine, built by J.

M. S. van Gelderen in 1997. Plans for the disks,

a top view, a back

view, a side view, and details of the

terminals and Leyden

jars. Pictures from the machine, seen from the front

and back sides, and from above here

and here.

Ricardo

"Rike" built this Wimshurst

machine in 1997, using LP records for the disks. It produces 7

cm sparks. Another view.

A beautiful large

Wimshurst machine (40 cm disks), built by James

T. Garavuso in 1998. A frontal view,

another, a side view,

a back view with the terminals in storage

position, another, and a view from above.

Details if the charge collectors,

neutralizers, and secondary

spark gap. This machine produces 12 cm sparks.

A Toepler

machine, built by Maximiliano

Guzman, from Spain, in 1998. The disks have 27 cm of diameter. A

later version used larger shields and a speed multiplier in the

crank.

A Wimshurst

machine, built by Raymond

Zaborski, from the USA, in 1999. The small intersector distance

and the neutralizers at low angle result in intense current and easy

self-excitation, but relatively small spark length.

A big motorized

Bonetti machine, built by Emery

Wayman, from the USA, in 1999. The machines has disks with 61 cm

of diameter, and produces sparks with up to 28 cm of length. Some

sparks from the machine: 1, 2,

3. The terminals balls have 7.5 cm of

diameter. Mr. Wayman has built also a similar, smaller, machine with

motors driving directly the disks.

A motorized

2 disks Toepler machine, built by Roger

Magnuson in 1999. The disks have 20 cm of diameter. Another

view. Note the small Leyden jars built in the terminal supports.

A classic

Wimshurst machine, built by Ronald

Coleman in 1999. Detail of the crank,

and of the charge collectors. The machine is

prepared for an upgrade with larger disks.

A Wommelsdorf

condenser machine with double rotation, built by Bert

Pool, following plans in a thesis

written by Wommelsdorf in 1904. Another view.

This machine is a compressed version of a multiple Wimshurst

machine, with sectors mounted between pairs of insulating rings,

interconnected through the external or internal edges of the rings.

One set of rings/sectors is held by the inner side and the other by

the outer side, and both turn in opposite directions.

A well built small

Wimshurst machine, made by Harry Boneham,

from Canada. The support structure was machined from aluminum, with

the disks having 18.5 cm of diameter. Another

view.

A Wimshurst

machine, built by Terry

Baines, from England, in 1999. With 30 cm disks, it produces

sparks with 3 cm.

A Wimshurst

machine, built by Alex

Rice, from England, in 1999. The machine has 32 cm disks, and

produces sparks with 10-11 cm of length. The spark is a double

exposure. A spark from the machine. In

2000, he built an improved machine.

A Wimshurst

machine, with 18" acrylic disks, built by John

Clark, from England, in 2000. It produces 3" sparks.

Dan

Bowlds, from Kentucky, USA, designed this original machine.

A bare disk rotates behind an insulating plate, that holds four wood

blocks painted with conductive ink. The lateral blocks are connected

to blades collecting charges from the back surface of the rotating

disk, and to Leyden jars made in the supports. The upper and lower

blocks are inductors, and are charged from the terminal blocks

through single corona points, also made of wood. Opposite to the

inductor blocks there are interconnected neutralizer blades. The

terminals are directly connected to the Leyden jars in the supports.

An elegant structure for a small motorized machine (the disk has 6"

of diameter) that works essentially as the Voss machine. The machine

requires an initial charge to start, and produces sparks with 1"

of length. Back view, Lateral

view. A video

about the machine.

A Wimshurst

machine with acrylic structure made by Scott

Nagel in 2000. With disks with 14.5" of diameter, it

produces sparks with up to 6". Another

spark. Note the separated small balls in

the positive terminal, and the good dimensions for the sectors in

the disks. The charge collectors, with some sharp corners, were

later modified.

What is probably

the largest working Wimshurst machine was

built by Paul Hendriksen

in 2000, for a technical show by ROVC

, in the Netherlands. The machine uses two glass disks with 2.15

meters of diameter (2 cm more than the large

machine built by Wimshurst in 1884), 12 mm thick. The output

voltage reaches 1 MV, producing sparks of up

to 1 meter. It turns at up to 100 rpm, producing 10 uA of current.

The output voltage is too high for Leyden jars, and so two copper

globes are used as distributed capacitors.

Details of the driving pulleys and a curious

discharging mechanism. A long spark,

another, and more sparks.

Eventually (by 2008), the machine was installed in the Technorama

museum, in Winterthur, Switzerland. Mr. Hendriksen also build

several other machines: A large Van de

Graaff generator, 2.5 meters tall, that produces 80

cm sparks. A sectorless

Wimshurst machine with 50 cm disks, that produces 28 cm sparks.

It uses an adjustable capacitor, seen here with its minimum,

medium, and maximum

capacitance, that allows control of the intensity of the sparks,

between a minimum and a

maximum, continuously. The

machine uses charge collectors

at just one side, and to start it a simple

friction rod is used. A hand-cranked Van

de Graaff generator, with an unusual toroidal terminal. A small

friction machine, with a 25 cm disk,

that produces 2.5 cm sparks. A curious

electric clock, powered by high-voltage between the two balls

below. Detail. Several high-voltage

demonstration devices.

A big Wommelsdorf

condenser machine with 10 55 cm disks was built by Serge

Klein, in France, in 2000. It can produce 25 cm sparks and up to

0.7 mA of current. Frontal views, from the left

and right sides, a view of the motor

that turns it, detail of the disks and

inductors, and another view. The disks

are composed of three disks glued with epoxy glue, with the central

disks separating two sets of intercalated sectors. The inductor

plates are also enclosed between plastic sheets glued with epoxy

glue. It works better with the neutralizer brushes removed, with the

gap between the disks and the neutralizer bars making the role of

the gap in the neutralizer circuit of the classic

machines. The machine was later upgraded to 12

disks, with better brush supports, in

an attempt to increase the output current. A spark

from the machine. Mr. Klein has also built other machines, as a

Dirod, a Wimshurst machine, a big Bonetti

machine, that produces 30 cm sparks, a machine

similar to a Felici machine with disks and

operating in open air, and a triplex

sectorless Wimshurst machine. Another view.

A nice Wimshurst

machine, built by Julian

Phillips, in New Zealand, in 2000. With 30 cm disks, it can

produce 7 cm sparks. Another spark,

and a description of it.

A very simple

setup was developed by Michael

Foster, in Los Angeles, USA, in 2001, to produce long

sparks by frictional electricity. He used nothing more than a

long PVC tube, a paper towel, a very simple Leyden jar capacitor,

and a special positive terminal to excite long sparks. A description

of his procedure.

a Wimshurst

machine, built by Luca

La Valle, in Rome, Italy. He built also other high-voltage

devices, as a Van de Graaff generator and

a Tesla coil.

A curious small

Wimshurst machine, designed by Fausto

Gazzi, in Bologna, Italy. Mr. Gazzi deals with ancient

instruments, and frequently makes restorations, as of this 4

disks Wimshurst machine.

A nice Wimshurst

machine, built by Chris

Kitching, from England, in 2001. Top

view, detail from the charge

collectors, and a spark with

14.5 cm produced by it. The acrylic disks have 36 cm of diameter and

4 mm of thickness, and are mounted on nylon bosses. The balls at the

spark gaps and joints are softened steel balls.

This

and this Bonetti machines I found at eBay.

They are similar to the machine described by R. A. Ford [8].

Builders unknown.

Tony

J. Meijers, in the Netherlands, built this nice Wimshurst

machine. With 37 cm disks, it produces 14 cm sparks. Note the

driving system, without crossed cords. Front

view. Back view. He built also this

Triplex Wimshurst machine, in 2000, that

with 41 cm disks produces 24 cm sparks. It also has a curious

implementation of the driving system, with the driving axle making

an angle of 10 degrees with the upper axle, so the crossed cord that

drives the central disks don't touch itself at the crossing. Front

view. Back view. Side

view. Other view. Assembly

of the disks. A thick 24 cm disk at the center and disks at the

outer sides impede sparking to the center of the machine. The Leyden

jars also have increased insulation.

Georges

Hublart, from France, built this Wimshurst

machine, motorized and with a curious construction. Side

view. With 33 cm disks, it produces 16 cm sparks.

Note the chains driving the disks. He has also other high-voltage

devices, as a Van de Graaff machine.

A Wimshurst

machine, with conductors insulated within PVC tubes and LP

record disks covered by adhesive plastic foil, built by Ben

Noviello, USA, in 2002. It produces 10 cm sparks.

A Wimshurst

machine, built by Rod Heidel, from

the USA, in 2002. With 20 cm disks, it produces 5 cm sparks. The

frontal structure is a capacitor.

A beautiful

Wimshurst machine, built in cherry wood

and brass by Gerald J.

Schaefer, from the USA, in 2002. The disks have 18" of

diameter. Side view, Frontal

view, With two demonstration devices. An

intense spark from it.

A symmetrical

Toepler machine, built by J.

Keverline, from the USA, in 2002. With 30.5 cm disks, it

produces sparks with up to 16 cm. The disks

have increased insulation with a material used to insulate tool

handles. This resulted in voltage high enough to pierce the spark

shields, that had to have their thickness increased to 4 mm.

A Wimshurst

machine that was once used for demonstrations at the Science

Museum, in London, England, restored in 2002 by Rob

Skitmore.

A large

Bonetti machine, built by Karl Kehrle, in Germany, in 2003. With

80 cm polystyrene disks, it produces 63 cm sparks, between a pair of

aluminim balls (8, 12 cm) at the positive terminal and a 30 cm

styrofoam ball covered with aluminum foil at the negative terminal.

The glass Leyden jars have 720 pF each. Mr. Kehrle wrote a book

[49] showing experiments with a similar sectored machine, that with

90 cm disks produces 47 cm sparks.

A Toepler

machine with 48 cm disks, built by Alain

Tramasaygues, from France, in 2003. This improved

version, with the inductor plates mounted inside a box, worked

better. This is a curious Van de Graaff

generator also built by him, that can produce 30 cm sparks. This

is his Van de Graaff with external belt. He

also built a Dirod machine. Another view.

A sectorless

Wimshurst machine, with 60 cm disks, built by Grant

Vincent Wells, in New Zealand. It can be operated by hand or by

a motor, has an electronic startup system, and produces sparks with

up to 24 cm.

These two

machines were built by Alan

Kerley. The larger machine is a Voss machine with a 21" and

17.5" disks, and the other is a small Wimshurst machine made

from CD disks.

This is a

Wimshurst machine made by Keith

Stuart, by 2000, in New Zealand. It produces 10 cm sparks. He

also restored an old machine (probably German, from around 1900) for

the Auckland Museum of Transport and Technology. Front

view, back view. By the end of 2003, he

made a curious combination between a symmetrical Toepler machine and

a Dirod. Side view, other

side, top view, end

view. With 12 cm disks, it produces 4 cm sparks.

A motorized

Wimshurst machine, made by Thomas Rapp, in Munich, Germany, in 2004.

Another view. The disks have 30 cm of diameter. More informations

and other projects can be found at the author's

site.

A Van

de Graaff generator, made by Richard Linder, in Burlington, USA.

The terminal is a stainless steel sphere with 45 cm of diameter. The

bottom roller is made of Nylon, and the

top roller of Teflon. The belt is made of

0.4 mm Mylar foil. Mr. Linder makes demonstrations

using it at the Burlington Science Center. For the 2004-2005 school

season, he built a larger machine, with

a 36" terminal. The 6" belt is made of vinyl impregnated

nylon. It produces arcs with 18" to 24" to a 1.5"

grounded sphere.

A Wimshurst

machine, built by Ricardo

Triches, in Brazil, in 2004. Another

view.

A big Van

de Graaff machine, built by Harold

Pollner, in California, USA, in 2004. The terminal has 30"

of diameter, the comumn is 9" PVC, the belt is made with 4"

Neoprene, and the machine is powered by a 1/4 hp 1725 rpm ac motor.

Excitation is by rolling friction between the belt and the lower

roller, that is a 4" PVC coupling mounted over a wooden core.

It produces 22" to 27" sparks, but from the rim of the

sphere opening to a grounded target electrode positioned below the

sphere, (as in the picture). Sparks from other points of the sphere

reach only 6" to 7".

A small Wimshurst

machine, with 20 cm disks, built by Hannu

Eloranta, from Espoo, Finland, in 2005.

A nice Wimshurst

machine, belonging to Dr.

Alistair Miller, England. The machine has 19" disks and

produces 6.5" sparks. It was built by Anthony Swift, that runs

a museum

dedicated to Victorian science in North Yorkshire, England.

A

motorized Wimshurst machine, built by

Peter Bradley,

in England. Spark picture. Another

spark.

A

curious friction machine built as a

Gramophone, by Kaj V.M.

Heiden, in the Netherlands. A spark.

Several

Wimshurst and Bonetti machines built by

Jarrod Kinsey.

Another view. He experimented also with

Wimshurst machines with sectors made with

conductive ink with excellent results. Some laser

experiments powered by electrostatic machines. An interesting

comparison of sparks. This is a

Holtz

machine completed in January 2009, with simple construction but

excellent performance, as seen on this

video. Another view.

A

Wimshurst machine, built by Christophe

Branger, in France, in 2006. Another

view, and another. Spark,

another spark.

A

Wimshurst machine, built by Emiliano

Salinas Covarrubias, from the Universidad de Sonora, Mexico. The

acrylic disks have 40 cm of diameter, and the structure is made of

polystyrene. It procuces 6 cm sparks.

A big

Bonetti machine, made by Hal

Pollner, in the USA, in 2006. With 25" disks, it

produces 11" sparks. A Van de Graaff generator is used to

excite the machine. Another

view.

A well built

Wimshurst machine, built by Leonardo

Giacomelli, in Italy, in 2006. All parts are made in machined

metals and acrylic. Front view, charge

collectors, lower pulleys, upper

pulleys and insulated neutralizers, and top

view. The disks have 40 cm of diameter, and it produces 16 cm

sparks.

Two Lebiez

machines, one hand-cranked and other

motorized, made by Milan

Manchich in 2007.

Two Wimshurst

machines made by Brian

Philips in 2007. First machine,

another view. It uses a flat

capacitor instead of Leyden jars. Second

machine, another view.

Several

machines and other devices, built by Luiz

Alberto Feijó Junior, in Brazil.

A

Wimshurst machine built by Vaughn

P. McDowell by 1986. Back view,

side view.

A

set of machines, Wimshurst, Voss and

Ramsden, built by Leonardo

Cannone, from Italy.

A

big Wimshurst machine, with 61 cm

disks, built by Haywood

Turner, from the USA.

Wimshurst

machines and Van de Graaff

generators, built by Harry

McCarty, from the UK.

An

electrostatic motor, built by Dan

Bowlds, from the USA.

A

Wimshurst machine, rebuilt by Rod

Heidel in 2008. The original is described above. One of the

Leyden jars exploded in a test due to glue vapors inside the PVC

tube. So, take care with ventilation on these constructions...

A

Wimshurst machine,

built by Carlos Alberto Vargas Alfaro, from Peru, in 2008. There are

some videos here.

A

Wimshurst machine built by Kevin

Acres in 2008. Side view. The machine,

compared to another machine built by his

grandfather 70 years ago. Back view. The

machine has 27 cm disks, and produces 8.5 cm sparks.

A

sectorless Voss machine, built by David

Hodges, in 2008. It uses combs in the charge collectors,

neutralizers, and inductor chargers.

A

Wimshurst machine, built by Rosalino

Trobbiani, from Italy, in 2008.

A

beautiful Wimshurst machine, built by

Jon Bodsworth, in

England. The machine was originally built 25 years ago, and recently

(2008) reformed. Front view, side

view. The glass disks, coated with shellac, have 22 cm of

diameter. The machine produces 6 cm

sparks. The structure was made with mahogany and brass, the

insulators were made with polyester resin, and the sectors were cut

from aluminum litho plates.

A

Voss machine, restored by Alan

Recce in 2009.

A

Wimshurst machine with classical look,

built by Douglas R. Johnson,

in 2010.

A

Wimshurst machine, also with classical

look, built by Leonard

Solomon, in 2010. Another view.

A

powerful Bonetti machine, built by Günter

Pecher, in Germany, in 2010. With 60 cm disks, it produces 40

cm sparks. Another view. He built

also this Van de Graaff generator, with

a 70 cm terminal, that produces 60 cm sparks.

A

great collection of electrostatic

machines, belonging to Jaap

Slikker, in the Netherlands.

A sectorless

Wimshurst machine built by PV

Scientific Instruments, being used by a company in the US

for tests of sensitivity of communication equipments to static

electricity, after some modifications to reduce leakage. The machine

is used with this ion emitter. A photo

of the machine in the dark, showing corona covering the positive

side of the disks.

A Bonetti

machine built by Jeffrey

Keverline, from the USA. Top

view. Long sparks (~30 cm).

Note the lower axle monted at an angle to avoid rubbing in the

crossed cord.

A Bonetti

machine with 49 cm disks made by Rosalino

Trobbiani, from Italy, in 2010. Side

view. Sparks..

A Wimshurst

machine, built by Douglas

R. Johnson. Second version,

improving the spark gap. Another,

smaller machine with 8" disks, built

in 2011 to test how small the sectors can be. With so small sectors

it needs an initial charge to start.

A Van

de Graaff generator, built by Julian

Phillips, from New Zealand. A description.

Sparks along the tube. More sparks.

Short sparks to a grounded sphere. Long

sparks.

A Van

de Graaff generator, built by Douglas

R. Johnson in 2011. It produces 8" sparks to the ground

terminal.

A Bonetti

machine, built by Leonard

Solomon in 2011. It has 14" disks and produces sparks of

almost 6". It can be easily excited by holding an electrized

PVC pipe near one of the disks (in front of a neutralizer is usually

the best) and holds charge for days in dry weather. Detail of the

terminal assembly. Tensioner.

Charge collector.

A nice Wimshurst

machine, built by Joachim

Oberhage, from Germany, in 2011. Details

of the machine. Another Wimshurst

machine built by him. The machines use wood supports for the

charge collectors, what I would not recommend, because wood is a bad

insulator unless very dry. Even so, they produce 8 and 2 cm sparks

with 30 and 20 cm disks.

A Wimshurst

machine with unusual structure, built by Francesco Trevisan,

from Italy. It uses two 40 cm disks powered by PC cooling

fan motors.

Some Van

de Graaff generators built by Kees

Kuyper, based on the commercial scientific toy "Fun

Fly Stick". One of them.

Another curious machine is this double

generator, where one of them is suspended by the belt, having no

support tube.

An artistic

Wimshurst machine, built by Hans

Wissmeyer, in 2013. With 24 cm disks it produces 6 cm sparks.

Another view, lateral view.

More details are available here.

A Wimshurst

machine, built by Jens

Thiergärtner, from Germany, in 2013. With 32 cm disks, it

produces 13

cm sparks. The construction is in acrylic and aluminum. The

neutralizer brushes use carbon fiber. Back

view.

Disassembly

for restoration of a Wommelsdorf

condenser machine, by Frank

Jones.

A

nice Wimshurst machine with the driving

axle perpendicular to the disk axle, built by Mark

Winquist, in 2015. It has quite thick

disks, 1/4" thick with 12" of diameter, but works

very well. It was initially designed

with the software Sketchup.

A big

Van de Graaff generator, built by Luis

M. Buresti, from Argentina. The terminal has 60 cm of diameter,

an the latex belt has 10 cm of width. The pulleys have 5 cm of

diameter and turn at up to 3600 rpm. The machine can reach 450 kV

(measuring by spark length between spheres) at 15-17 μA. He also

built this Greinacher multiplier, that

can reach 300 kV. at 100 μA. The devices are being used in

experiments in nuclear physics.

The first

electrostatic machine [15], was built by Otto

von Guericke [16] by 1663, using a sulphur globe frictioned by

hand. The globe could be removed and used as source for experiments

with electricity. A picture of a working replica

of the machine, from the University of Oldenburg.

Another important

early researcher was Francis Hauksbee, that built several machines

using glass globes [50][53] and cylinders

by 1705.

The friction

machines were gradually improved through the works of many

researchers. This is the machine with a glass globe of the abbot

Nollet (~1740) [7]. Eventually, the machines took a stable form,

with leather friction pads (Winkler, 1744), glass globes (Bose,

1751), and insulated charge collectors. Demonstrations

with these machines were common.

Watson's

machine [51][52] (1746) had a large wheel turning several glass

globes. The prime conductors were a sword and a gun barrel suspended

from silk cords. Watson made many experiments with the Leyden jar,

then recently invented.

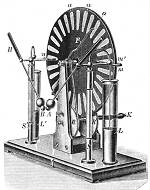

A Ramsden

electrostatic friction machine [2]. Another

picture [7], another [12], a good

drawing [17], and a picture of a large

machine [14]. The first popular machine using a disk (1766).

Designed by J. Ramsden, an instrumentist that also designed many

other good instruments in the 1700's. A beautiful restored Ramsden

machine, found at eBay in

1999. Photos by Fausto Gazzi.

This large machine I found in a museum

in Geneva, Switzerland. A simpler machine built by myself is shown

in the first section of this page.

The machine of Le

Roy (1772) [50][p26] was suitable for the production of long

sparks, due to the high insulation between the friction pads and the

charge collectors (see a more modern version as the Winter machine,

below).

This large

disk machine (1785) with 1.6 m disks can be seen at the Musée

du Conservatoire Nacional des Arts et Metiers, In Paris, France. On

its base is written the motto at the top of this page. There is a

picture of it in [21].

A brass

model of a Ramsden machine. A curious decorative object,

possibly from the 1930's or before. The disk has 3.5" of

diameter. Photos sent by Blake

Awbrey.

A Nairne

electrostatic friction machine [7], built in 1770, consists in a

glass cylinder, a friction pad in one side, and a charge collector

in the other, both connected to insulated conductors. Another

one. The machine was used for medical purposes.

The van

Marum electrostatic friction machine (1784) [9]. By moving the

two curved bars with charge collectors, it was possible to collect

charge from the disk (bars as shown), or from the friction pads

(bars turned 90 degrees), producing voltage with any polarity, as

shown here. Van Marum is also known for the

big machine [16][21] that he had made in

1784, that is now in the Teylers

museum.

A similar machine,

now in the Deutsches Museum, Munich, Germany, belonged to Georg Ohm

(1830?)[21]. Another view. Photos sent by

Hans Bussmann

(I could not find it there in september 2008).

A belt

machine [50] built by N. Rouland by 1785, had a charge collector

with blades that collect charges from a silk belt rubbed by two

grounded tubes covered with hare fur [21].

An old

friction machine using a glass disk. Another

picture of the same machine. Photos sent by Don Day.

A Winter

electrostatic friction machine. One of the most efficient

friction machines. A picture from an old

book [3], and another, from H. Pellat

[7]. This was the last popular structure for friction machines, as

shown in these catalog pictures from the 1920's: this

and this are from [17], and this

is from [22]. The characteristics of the machine are the disk

frictioned at one side, at both faces, with a pair of charge

collectors at the other side, shaped as rings with points turned to

the disks. Sometimes a large wood ring (Winter's ring) with a

metallic core was attached to the terminal, increasing its

capacitance. A double adjustable version can be seen on the first

picture.

The Woodward

machine (1840) [43][21] was a modified Ramsden machine, with the

prime conductor located above the disk, or disks, saving some space.

It could also generate negative voltage,

by mounting the upper friction pad in place of one of the charge

collectors. This double machine is in

the University of Porto, Portugal. Partially disassembled.

Pictures by Marisa Monteiro.

The Armstrong

hydroelectric machine [2], a friction machine using steam as

charge carrier (1840). It is just an insulated boiler producing a

steam jet mixed with water droplets. A better picture is here

[9]. Very powerful machines of this kind were built for research.

The Lorente

generator. A triboelectric machine composed of four cylinders

that roll together without friction, under a slight pressure. The

two outermost cylinders are metallic, and the two central cylinders

are of distinct insulating materials (nylon and teflon). Opposite

charges are collected in the metallic cylinders. The basic machine

produces voltages of some tens of kV, but several modules can be

stacked for more voltage. A coaxial version

is also possible. Pictures from actual models are here

and here. This device was invented and

patented by G. Lorente,

who sent the pictures.

Rolling friction

is also commonly used in models of the Van de

Graaff generator, although the principle of the charge

generation system on those machines is a mix of friction and

influence.

The largest classical

friction machine was built for the "Royal Panopticon of

Science and Arts", in 1854.

The first rotating

influence machines were the "doublers of electricity". The

first was Nicholson's doubler [p14]

(1788). It was a rotating implementation of Bennet's

doubler (1787), a device based on Volta's

"electrophorus" (1775) [p110],

that allowed great multiplication of a small initial charge by a

series of repeated operations with three

insulated plates. It was used as instrument for the amplification of

small charges, but could also generate electricity starting from

natural imbalances. The original machine proposed by Nicholson

didn't require a connection to ground, but versions with explicit

ground connections are also possible, as this

[28] or this [65][66], similar to the

one designed by Desormes and Hachette

[p115], and this,

built by Wimshurst [p14]. An actual

machine exists in the Musee

d'histoire des sciences, in Geneva, which looks as this

machine (John Read's doubler) [p106][p114].

A version of Nicholson's doubler

used by Volta can be seen at the Tempio

Voltiano. See my Nicholson's

doubler. A similar implementation, where the two plates that

are fixed in Nicholson's device rotate, is Bohnenberger's

machine (1798) [4]. Bohnenberger designed several other

doublers, as this automated version of

Bennet's doubler and this variation

of Nicholson's doubler (1801) [p107], both operating with

back and forth movements. See my

Bohnenberger's machine.

Multipliers based

on a different system are also possible, as Péclet's

condenser (1841) that increases the charges linearly with the

number of operations [p87] and a

multiplier with 4 plates invented by Pfaff and

Svanberg (see my version)

that combines addition and multiplication [54]. Multipliers directly

based on the electrophorus were studied, by Volta himself [p110]

and Lichtenberg.

A similar adding

device was Cavallo's multiplier (1795),

where a movable insulated plate was moved back and forth,

alternatively being grounded under the influence of a second

previously charged plate, and touching a third insulated plate close

to a grounded fourth plate. After some cycles, the grounded plate

would be removed, causing the accumulated charge at the third plate

to rise its potential to about the potential of the second plate

times the number of cycles [4].

Two Cavallo

multipliers can be combined in Wilson's

machine (1804), a curious machine that incorporates

essentially the same idea of the symmetrical rotating machines

developed much later.

One of the

scientists that studied doublers was Erasmus Darwin. His

"commonplace

book" contains a sketch of a

doubler, that appears also in [p14],

that is probably the first drawing of these devices. His book

"Phytologia" contains a drawing of a "pendulum

doubler", attributed to Bennet (see here).

The next

development was of symmetrical influence machines, using influence

to generate new charges and Faraday's shielding effect to collect

them. The first was Belli's machine

[4][p14] (1831), the first symmetrical

influence machine. My Belli machine.

A picture of an elaborated actual machine.

Belli developed also a different machine using the same principle,

shown here. The same basic structure

appears in Lord Kelvin's "replenisher"

[2][p92] (1867), in schematic

representation, and as constructed [12]. A

simple machine built with insulated curved metal plates, used as

part of measurement instruments. Here

is a ray-tracing picture similar to a machine that I built by 1973.

The rotation of the central insulating bar with two metallic

carriers, touching the four contacts, causes accumulation of

opposite charges in the outer plates. Another similar machine was

the Varley machine [26] (1860).

A device that can

be considered an influence machine is Einstein's "Maschinchen"

(little machine). It was a mechanical voltage multiplier resembling

a multistage Belli machine without feedback. This

paper describes it.

A curious

machine [18] that appears to be similar to Belli's machine, if

the lateral brushes are connected to the fixed plates. The same

machine appears illustrating this advertisement

(1962) but with an added set of brushes installed, to separate the

output circuit from the inductor plates, as in the Voss machine.

A machine simular

to a double electrophorus, described by G.

Fuller [p123]. It uses combs with points

to spread charge at both sides of an insulating plate, and then uses

two metal plates as in the electrophorus to obtain charges from it.

A regenerating system uses the extracted charges to reinforce the

charges in the insulating plate.

The Piche machine,

or Bertsch machine (1866) [7]. One of the

simplest influence machines, uses an insulator plate (I), that is

separately electrized by friction, and used to generate charges in

the rotating disk by induction. See the original letters about this

machine in the references. A similar

device is the Dubrowski machine [22]. This

type of machine was called "continuous electrophorus".

The Carré

machine [6] (1868). A friction machine below charges by

induction a fast rotating disk, that transfers charge to the upper

conductor. It is similar in operation to the Bertsch machine, but

regenerates the charge in the inductor. A

better picture [7]. A variation [14]

with slanted combs. A ray-tracing drawing.

A photo from an actual machine, sent by

John

Newman. A machine with a double terminal.

The Van de

Graaff generator [p4][8] is an evolution of this machine, with a

belt instead of the disk, and a more efficient charge collector at

the top. This machine is in a museum in

Switzerland. Another machine, in a Museum

in Spain.

A double

Bonetti machine from the same museum, with curiously shaped

neutralizer combs (?).

The Cecchi

machine, or "dielectric machine" (1868) is similar to

the Carré machine, and was developed a few months before [p118],

by Filipo Cecchi [p119], an italian researcher.

A version

with double excitation of the Cecchi/Carré machine can be seen

at the Museo

Galileo, in Florence. Another view.

The two friction machines, with glass and ebonite disks, generate

opposite charges, and the central ebonite disk is used as a current

multiplier.

Another antecessor

of the Van de Graaff generator is Righi's

electrometer [p55] (1872), that used a rubber string with brass

rings for charge transport, and a hollow sphere as charge collector.

A picture of this machine [41]. Similar

machines are also discussed in [p59] (1875), as a bipolar

machine, that must have grounded pulleys, and another,

that adds a neutralizer circuit and can use insulated pulleys.

Righi studied also

a belt machine [p59], that antecipates a

regenerative charging system used in some Van de Graaff machines,

and shows a curious polarity reversal phenomenon, where for some

time the belt operates with bands of both polarities.

Righi designed

this big Holtz machine [41] (~1875), used

at the Regio Istituto Tecnico de Bologna for teaching and research.

A drawing of a similar machine [42].

A Lord

Kelvin's water machine (1867) [1][p91].

It is an influence machine that uses water droplets instead of

rotating carriers. It works in the same way of the 2

disks Toepler machine. Another picture

[6] of a similar machine. An improvement of this machine using two

additional units for output, avoiding the discharge of the

inductors, was proposed by Fuller in 1888 [p103] [ p62].

A different version was proposed by

Sylvanus Thompson in 1887 [p104].

The Schwedoff

influence machine [9][13][29] (1868). A very strange machine.

The lower plates form a modified Holtz machine, with inductor plates

replaced by combs (dotted lines) charging the lower surface of the

lowest fixed disk with charge taken from the charge collectors. This

first machine provides bias for the sectors in the lower plate of

the upper assembly (the even-numbered ones with one polarity, the

others with another), that form a current multiplier. The output is

taken between the two insulated sets of combs over the upper,

rotating disk. This picture from the original

paper [p46] shows more clearly the connections. This is the

charge collector [p46] that completes the

machine.

A Toepler-Holtz

machine, or Voss machine with classical design. From a catalog from

the 1920's. Two more pictures here and

here. Pictures found in the Gemmary's

forum.

Several

Toepler-Holtz, or Voss, machines from [17]: A simple

machine, another, a double

machine, a quadruple machine (see one

here), and a multiple

machine. Two more simple machines from [18]: this

and this. And another

one, from [22].

A magnific

quadruple Voss machine, at the museum of

the University of Pavia, Italy.

Clarke's

lighter was a small Voss cylindrical machine used as a lighter.

Photos by Frank Jones.

The Shall

machine [64][5] was a variation of the Voss machine with the

inductor plates suspended behind slowly rotating insulating disks.

The idea was to prevent polarity reversals caused by charge

accumulation at the opposite sides of the inductors in machines with

fixed disks.

A Holtz-Wimshurst

machine [4][23], simple and with a frictional

starter [4][23]. These were Holtz-type machines with several

disks and improved construction, as the inductors fixed in separate

square glass plates, developed by Wimshurst by 1878.

The Kundt

machine [4] (1868) was a mixed friction-influence machine, similar

to a Bertsch machine with the back side of the disk frictioned by a

friction pad with a silk flap attached, as in a friction machine. At

the front side are positioned two charge collectors, as in the

Bertsch machine. A similar machine was the Cantoni

machine (1869), that added a third charge collector at the back side

of the disk, so the machine can also be used as a friction machine.

A good picture of

a classic Wimshurst machine (1883) [1]. A

Line drawing of the same picture [2].

A Wimshurst

machine [6], similar to one that exists in the Museum

of the UFRJ Engineering School, and that I restored. Another

[14] similar machine. That machine was built by F. Ducretet and E.

Roger, Paris, and originally should look as in this

(front) and this (back) ray-tracing

drawings. Here are comments about the

restoration and more pictures. This is

how it is now, compared with my 1974 Wimshurst. A large spark

produced by the machine in a demonstration. Another picture, showing

two of these machines connected as a generator

and motor pair [24]. These pictures [23] show discharge images

on photographic plates obtained with one of these machines. A

positive discharge, and a negative

discharge. A multiple machine from the

same instrument builder, at the University of Porto, Portugal.

Here is another

Wimshurst machine from the same museum that I restored

(ray-tracing), a picture of it, and some

comments about the restoration.

The largest

Wimshurst machine ever built is presently at the Science and

Industry Museum in Chicago, USA. It was built in England in 1885,

with 7 foot glass disks 3/8 inch thick, and produced sparks with 22

inches. This picture is from Engineering, Vol. 39, 1885, scanned

from [23] (also appears in [4][5][8][26]). More informations

and pictures about this machine.

More Wimshurst

machines, from [14]: A large simple

machine, a double machine, a quadruple

machine, and an octuple machine. And also

two machines from [15], with ebonite disks

and Leyden jars with two sections, and with glass

disks. Two more large machines from [22]: A simple

machine and a quadruple machine.

Wimshurst

machines, from the collection belonging to Louie

Scribner: A French machine (Bonetti),

and a German machine (Leybold, 1901).

Wimshurst machines

that have full construction details in [4][23]: A laboratory

machine, a long spark machine, and a

twelve plates machine. Designs by J.

Wimshurst.

A "Voltana"

Wimshurst machine [34](1921), used to run an electrostatic

motor, and a bank of Geissler tubes. A

larger machine, a smaller

machine, another machine, more Geissler

tubes being lighted, lighting a spinning

Geissler tube, charging a Leyden jar,

and charging a spring, that expands when

charged [35].

Several machines,

from [38], that illustrate the state of the art by 1900: A classic

Wimshurst machine made by Bonetti, with Leyden jars that support

the terminals, a complex double machine and

a large multiple machine made by Ducretet,

and a machine with large conductors, that

act as capacitors. The classic Bonetti

sectorless machine, a multiple Bonetti machine,

and a double Bonetti machine.

Some multiple

Wimshurst machines: A double machine,

built by the instrument builder E. Balzarini,

similar to the machines that appear in its 1907

catalog. Note the triple brushes at the neutralizers. A

quadruple machine, built by Newton

& Co. Back view. Detail from one

of the charge collector assemblies.

Pictures from eBay auctions.

Wimshurst machines

with an orthogonal drive system were built

by companies as Central Scientific Co. A machine

with the Leyden jars serving as terminal supports. A small unusual

German machine. A larger

machine, and a big machine . One

of the pulleys below is driven by the crank. The other runs freely

1.

A Wimshurst

machine with cast iron structure,

including the neutralizers 1.

The Wimshurst

machine can also be built with cylinders

instead of disks [4][23]. A more practical structure was designed by

Lemström [5][8] (1899), with the two

cylinders turning around a fixed central axle, that also holds

the internal charge collectors and

neutralizers. The axle was separated in

two sections by an insulating block at the center. The machine was

kept warm, dry, and ventilated by a heating system and the sides of

the cylinders, shaped as fans. See his patents.

The Wimshurst

alternating machine (1891), that generates alternating voltage,

synchronized with the rotation, with a polarity reversal at each 3/4

of rotation of the disk. The operation of this machine was

considered difficult to explain [5]. A single disk with sectors at

both sides, alternating, rotates between two pairs of

collectors/inductors. Picture from Engineering.

A triple

Bonetti machine [11]. This kind of multiple machine was used in

early X-ray work.

By June-October

1999 I restored a similar quadruple

Bonetti machine, built by Radiguet & Massiot (~1910), for my

university's museum. Some pictures of

the machine during initial tests and a report about the

restoration are available.

Another double

Bonetti machine [26], with similar features.

A cylindric

Bonetti machine [11]. A compact design with high current output.

This appears to be a large machine built by

Bonetti by 1894, where the cylinders had 50 cm of diameter and

height [p78]. Another cylindric machine

[26].

A machine that

appears to be a sectored Holtz machine

[22], said to be quite powerful. There are fixed inductors on the

back plate, that are charged by sectors at the back of the rotating

disk through brushes that project through two holes in the fixed

disk.

A motorized

Voss machine with a fully sectored rotating disk [26].

P. V. Schaffers

(1885) [4][5][p29][p32] described a machine that is essentially a

Wimshurst machine with the charge collectors at different positions,

with brushes at the charge collectors. The Schaffers machine works

as a combination of the Wimshurst machine and the Holtz machine of

the second kind, producing higher current (schematic).

A (bad) picture of a Schaffers machine

[26].

"Pneumatic

machines", operating in compressed air or other gases, were

developed after experiments by W. Hempel described in 1885. The high

pressure increases the breakdown voltage, allowing greater voltages

and currents to be obtained.

A Wehrsen

machine [1][26][27][32][34][p77] (1907). Wommelsdorf's idea, it

is a highly insulated sectored Holtz-style machine with sectors

embedded in the rotating disk, contacted

through small buttons, and inductors [34]

also totally insulated behind celulloid plates. Some machines had

corrugated sectors for greater surface area, what increases the

output current [5], or mounted at different planes for higher

insulation [26]. They had switches to allow the direct connection

between the inductors and the output circuit, for startup as a

"replenisher" machine [32]. Two better pictures from [17]:

A large machine, and a small

machine. A simple machine, and a large

machine, from [22]. A machine with direct motor

drive [26]. A similar machine [p77].

Wehrsen's "Mercedes" machine

[34][26], with one rotating disk, and with two

rotating disks, one at each side of the fixed disk. A similar

machine, built in 1911, exists in the

Cavendish Laboratories, England. left view,

right view, back view.

Detail from the switches, and from the

central inductor plates. The machine is

normally under an enclosure, and was disassembled for cleaning and

investigation of why it doesn't work anymore in 1999. Photos sent by

Tacye Phillipson.

The Wommelsdorf

condenser machine [1][17][18][p84] (1902-1920) was the last of

the classical disk machines. It was basically a sectored Voss-style

machine with double induction plates, one pair at each side of the

rotating disk, and with all the sectors and inductor plates enclosed

in ebonite plates. Some models had a switch in the middle of the

neutralizer bar. A simpler model [17]. In

the last versions, the disk had a full set of embedded sectors,

monted in alternate groups separated by one or two thin insulating

disks. The sectors were touched only at the borders of the disk by

brushes running in a V groove there. The

ebonite disk was covered by a material (celluloid or bakelite)

resistent to deterioration caused by ozone and other gases produced

by electrical discharges. [5][8]. Schematic

diagram [27]. Versions with multiple sections were also built, with

some versions combining different charging systems for the

inductors, with alternate sections charging the inductors from

brushes at the edge of the disks and others from brushes touching

the sides of the disks, as in a Holtz machine. Another

version [22] with older design, totally enclosed and with fixed

contacts for the neutralizer. Partial schematic

diagram. A similar machine [p80], another,

an open machine, and a very

large machine [p81][46] along with a small

machine. A condenser machine powered by a steam

engine [46]. Wommelsdorf designed also machines with pairs of

disks rotating in opposite directions [45][p83], similar to multiple

Wimshurst machines, as this

[46], a triplex Wimshurst machine with a

central disk accessed through the edge.

Manual

of static electricity, from Wommelsdorf's company BEG.

Several of the

papers and patents

by Wommelsdorf are available here. See also my

Wommelsdorf machine.

See some tables

with the performances of several machines.

The Pidgeon

machine [26] was a Wimshurst machine with fixed inductors

positioned in a way that increases the induction effect. Fixed

inductors with same polarity of the opposite disk were placed

surrounding, insulated, each neutralizer brush. The sectors were

embedded in the disks [5][26][p53][p54][p111]. Pidgeon studied

also machines based on "triplex

Wimshurst" sections (double machines with a single

central disk), with enclosed sectors, that produce more current. The

first Pidgeon machine had a quite strange structure

[p111], and the disks had slanted sectors for more uniform

induction.

Piggott made a set

of experiments with radiotelegraphy and "antigravity"

using a compact double Wimshurst machine enclosed in a pressurized

box. Drawings from his patent (1911)

showing the machine. Front view, side

view, top view.

A "Dirod"

generator. A modern electrostatic machine, designed by A. D. Moore

[10]. It is a cylindric machine similar to the Belli machine, or

Lord Kelvin's replenisher, with metal rods as carriers. The output

is taken at the inductors.

Another machine

described in A. D. Moore's book [10] is the "shake-sphere"

machine. It is electrically equivalent to the symmetrical

Toepler machine or the earlier Wilson's

machine.

From the 1940's to

the 1960's, Nöel J. Felici, in France, developed a series of

high-power electrostatic generators [40],

initially for applications in research. This

site,

by Lyonel Baum, contains many informations about his work.

Large medical

electrostatic machines were common around 1900, used for

electrotherapy and radiography, and were probably the most elaborate

of these machines ever built.

See also the several machines that I have

built, in the section "my machines", above. The linked

pages have many informations about the machines.

Electrostatic

machines are electromechanical devices that produce "static

electricity", or electricity at continuous (DC) high voltage.

They were fundamental in the early studies about electricity, started

in the XVII century, in the form of "friction machines",

and their development culminated at the end of the XIX century with

the development of powerful "influence machines". Today,

some specialized uses for them continue to exist, but they are mostly

seen as demonstration devices in physics laboratories, with much of

their history forgotten.

Electrostatic

machines are electromechanical devices that produce "static

electricity", or electricity at continuous (DC) high voltage.

They were fundamental in the early studies about electricity, started

in the XVII century, in the form of "friction machines",

and their development culminated at the end of the XIX century with

the development of powerful "influence machines". Today,

some specialized uses for them continue to exist, but they are mostly

seen as demonstration devices in physics laboratories, with much of

their history forgotten.