A 6th-order

Tesla Magnifier

(or a transformer-coupled triple

resonance network with distributed load capacitance)

By April 2003 I started

experiments with a 6th-order Tesla magnifier, in an attempt to

verify if the design method developed for triple resonance networks can be also

useful for an application intended for the production of sparks

and streamers, a variation of the classical Tesla

coil. The 6th-order Tesla magnifier consists in a

low-impedance primary LC tank circuit L1-C1

magnetically coupled to a medium-impedance tank L2-C2,

used as a "driver" for a high-impedance resonator

formed by the third coil L3 and its

distributed load capacitance C3. The device

is powered by a neon sign transformer (NST) that has a spark gap

across its output. The NST charges C1 to the

firing voltage of the gap, and while the gap conducts the circuit

executes a transient involving symultaneous oscillations at three

frequencies that, with proper design, ideally transfers all the

energy initially stored in C1 to the

distributed capacitance C3, producing pulses

of very high voltage because C3<<C1.

I had previously experimented with a directly

coupled version of this circuit, that resulted in just

reasonable performance. Directly coupled multiple

resonance networks have the voltage gain associated with the

number of oscillation cycles required for complete energy

transfer, and so are quite inflexible. With the use of magnetic

coupling, it's possible to remove this dependency, and so, in

principle, to achieve better efficiency by reducing the energy

transfer time.

By April 2003 I started

experiments with a 6th-order Tesla magnifier, in an attempt to

verify if the design method developed for triple resonance networks can be also

useful for an application intended for the production of sparks

and streamers, a variation of the classical Tesla

coil. The 6th-order Tesla magnifier consists in a

low-impedance primary LC tank circuit L1-C1

magnetically coupled to a medium-impedance tank L2-C2,

used as a "driver" for a high-impedance resonator

formed by the third coil L3 and its

distributed load capacitance C3. The device

is powered by a neon sign transformer (NST) that has a spark gap

across its output. The NST charges C1 to the

firing voltage of the gap, and while the gap conducts the circuit

executes a transient involving symultaneous oscillations at three

frequencies that, with proper design, ideally transfers all the

energy initially stored in C1 to the

distributed capacitance C3, producing pulses

of very high voltage because C3<<C1.

I had previously experimented with a directly

coupled version of this circuit, that resulted in just

reasonable performance. Directly coupled multiple

resonance networks have the voltage gain associated with the

number of oscillation cycles required for complete energy

transfer, and so are quite inflexible. With the use of magnetic

coupling, it's possible to remove this dependency, and so, in

principle, to achieve better efficiency by reducing the energy

transfer time.

My system was designed for operation in mode 3:4:5, what means

that the energy transfer transient has oscillations at three

frequencies that are in this ratio. I used the same C1,

L3, and C3 that I had

prepared for previous experiments. With

the help of the design formulas shown here,

the remaining elements L1, L2,

C2, and the coupling coefficient k12

can be calculated. The program mrn6 can

make the calculations and plot the expected ideal

waveforms. The result was:

C1 = 5.08 nF

L1 = 62.02 ÁH

C2 = 79.64 pF

L2 = 3.948 mH

C3 = 9.8 pF

L3 = 28.2 mH

k12 = 0.3504

Voltage gain: 22.77

Energy transfer time: 6.606 Ás

The driver transformer was designed

with the help of the program Inca, that

can calculate inductances and mutual inductances with great

precision. L1 was made as a flat coil and L2

as a short solenoidal coil. This configuration produces the

required quite high coupling, but doesn't present serious

insulation problems.

Primary: 14 turns; internal radius = 8 cm; external radius =

12 cm; wire diameter = 1 mm (#18).

L1= 0.06207 mH

Secondary: 176 turns; length = 10.2 cm; radius = 7.4 cm; wire

diameter = 0.51 mm (#24); height above L1 =

7.5 mm

L2= 3.949 mH

Mutual Inductance M = 0.1734 mH

Coupling coefficient k12 = 0.3501

The capacitance C2 consists in the

distributed capacitance present in the interconnection between L2

and L3 and in a lumped capacitor that

completes it to the required value. The distributed capacitance

can be estimated as somewhat larger than the sum of the Medhurst

capacitances of L2 (7.1 pF) and L3

(5.6 pF), for the configuration used. To determine how large the

lumped capacitor must be, I made a low-power test using a

low-impedance square-wave generator, set to low frequency, in

place of the spark gap, and used a variable capacitor as C2.

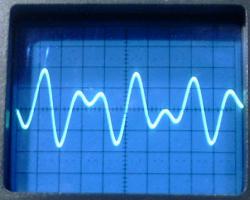

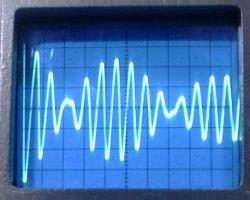

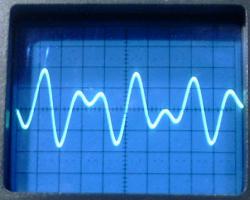

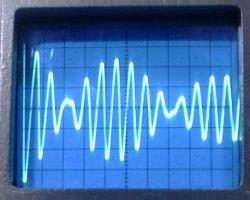

The waveforms observed at the transitions of the square wave are

similar to the ones that would be observed starting with a

charged C1. The waveforms below were obtained

with a lumped C2 = 62 pF, and the antenna at

the top load at its minimum length. They correspond closely to

the ideal waveforms.

VL1, VL2,

and VL3. 2 Ás/div.

The energy transfer in 6.6 Ás can be observed.

The three resonance frequencies were measured as 232, 307, and

385 kHz. The ideal values would be 228, 304, and 380 kHz. The

obtained precision was quite good, with errors of 1.8%, -1%, and

-1.3% in the frequencies.

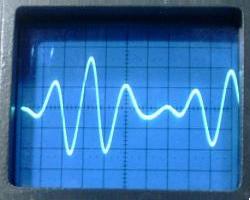

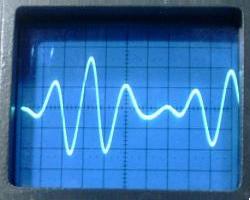

Without a lumped C2, the

system falls close to a higher mode, that uses the remaining

distributed C2 = 17.64 pF. The mode 6:7:14

would result in L1= 61.77 ÁH, C2=

24.63 pF, L2= 3.819 mH, and k12=

0.3453, for the same other elements. The energy transfer for this

mode occurs in 3.5 cycles, close to the observed. The input and

output voltages are similar to what occurs in a two coils system

operating in mode 6:7, a mode that I could obtain with my Tesla

coil only when I connected it as an Oudin coil. The magnifier

configuration results in faster energy transfer even when a

lumped C2 is not used.

VL1 with a lumped C2

and without. 5 Ás/div.

The construction of a suitable C2 is not

easy. Simulations show that C2 has to sustain

26 kV for a gap voltage of 5 kV, during the energy transfer, and

somewhat more after the gap quenching. What I tried initially was

to make a pair of Leyden jars using

plastic cups (polypropylene), each with 124 pF. My reasoning was

that with less voltage and more metal area in the capacitors, the

losses would be smaller. The performance of the system in a full

power test, however, was not as good as the performance of a

conventional Tesla coil with the same

elements. It was just a bit better than what I had obtained with

the directly coupled 6th-order system.

Without the lumped C2, the performance was

significantly better, close to the performance of my Tesla coil. C2 was

evidently consuming significant energy, with intense corona

around the edges of the plates, and becoming warm quickly. A

better approach would be to make a big "mmc" capacitor,

by connecting several medium-voltage commercial capacitors in

series (look here for a

2:3:4 magnifier made by Terry Fritz).

Another problem that could be causing the poor performance is

that with narrow "notches" in the primary waveforms,

the primary gap could not be "quenching" (ceasing to

conduct) when the energy transfer is complete, while this

continued to happen in the version with a distributed C2

only, that has more gradual "notches". Further tests

will reveal what is happening.

Still another possible cause of poor performance is that the

rms voltage at the output of a 6th-order system, for the same

peak output voltage, is smaller than the rms voltage in a

4th-order system. During the energy transfer, this is caused by

the "second order" notches that the 6th-order system

produces. Ignoring losses, in a 4th-order system, for all modes

the ratio between the rms value of the output voltage and the

peak voltage is 0.5 while the gap conducts. For a 6th-order

system it varies from 0.4375 for mode 1:2:3 to 0.4330 for high

modes (0.4341 for mode 3:4:5). After the quenching of the gap,

the oscillation of the energy in the 4th-order system formed by L2,

C2, L3, and C3

may also reduce the rms output voltage.

Spark pictures soon.

Programs that can design and simulate the behavior of this

system, and others, can be found here.

Extensive materials about Tesla coils can be found in the

archives of the Tesla list.

[1] See the papers about "multiple

resonance networks" here.

Warning:

This device is powered by a

power source that has enough voltage, and specially enough

current, to give a fatal shock. The NST, the terminals of C1,

L1,

C2,

L2,

and the spark gap must not be touched in any circunstance while

the system is energized. The high-voltage arcs are also not safe

to touch. They may cause burns, and the current is intense enough

to cause internal body damage.

Created: 11 May 2003 (optimized for 800x600).

Last update: 12 May 2003

Created and maintained by Antonio Carlos

M. de Queiroz

See also: Electrostatic Machines

By April 2003 I started

experiments with a 6th-order Tesla magnifier, in an attempt to

verify if the design method developed for triple resonance networks can be also

useful for an application intended for the production of sparks

and streamers, a variation of the classical Tesla

coil. The 6th-order Tesla magnifier consists in a

low-impedance primary LC tank circuit L1-C1

magnetically coupled to a medium-impedance tank L2-C2,

used as a "driver" for a high-impedance resonator

formed by the third coil L3 and its

distributed load capacitance C3. The device

is powered by a neon sign transformer (NST) that has a spark gap

across its output. The NST charges C1 to the

firing voltage of the gap, and while the gap conducts the circuit

executes a transient involving symultaneous oscillations at three

frequencies that, with proper design, ideally transfers all the

energy initially stored in C1 to the

distributed capacitance C3, producing pulses

of very high voltage because C3<<C1.

I had previously experimented with a directly

coupled version of this circuit, that resulted in just

reasonable performance. Directly coupled multiple

resonance networks have the voltage gain associated with the

number of oscillation cycles required for complete energy

transfer, and so are quite inflexible. With the use of magnetic

coupling, it's possible to remove this dependency, and so, in

principle, to achieve better efficiency by reducing the energy

transfer time.

By April 2003 I started

experiments with a 6th-order Tesla magnifier, in an attempt to

verify if the design method developed for triple resonance networks can be also

useful for an application intended for the production of sparks

and streamers, a variation of the classical Tesla

coil. The 6th-order Tesla magnifier consists in a

low-impedance primary LC tank circuit L1-C1

magnetically coupled to a medium-impedance tank L2-C2,

used as a "driver" for a high-impedance resonator

formed by the third coil L3 and its

distributed load capacitance C3. The device

is powered by a neon sign transformer (NST) that has a spark gap

across its output. The NST charges C1 to the

firing voltage of the gap, and while the gap conducts the circuit

executes a transient involving symultaneous oscillations at three

frequencies that, with proper design, ideally transfers all the

energy initially stored in C1 to the

distributed capacitance C3, producing pulses

of very high voltage because C3<<C1.

I had previously experimented with a directly

coupled version of this circuit, that resulted in just

reasonable performance. Directly coupled multiple

resonance networks have the voltage gain associated with the

number of oscillation cycles required for complete energy

transfer, and so are quite inflexible. With the use of magnetic

coupling, it's possible to remove this dependency, and so, in

principle, to achieve better efficiency by reducing the energy

transfer time.