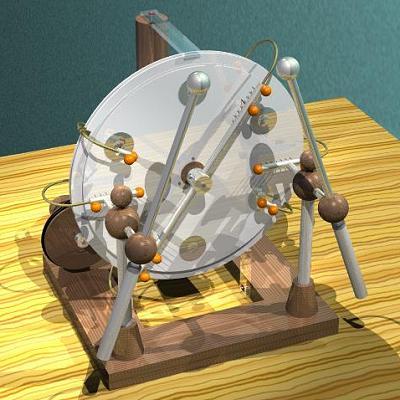

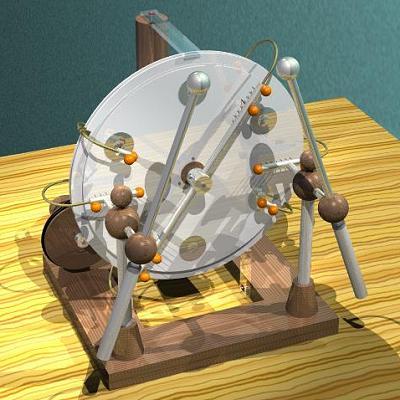

A double Voss electrostatic influence

machine

The Voss machine, invented in 1880, is

a derivation of the Holtz and Toepler machines (1865), and so is also

known as the Toepler-Holtz machine (or even Toepler-Voss machine,

as Toepler also developed a similar machine by that time). This

design was very popular by the end of that century, being

extensively used for laboratory and medical applications,

including use as power supply for early X-Ray machines. It

consists of a fixed disk and a rotating disk, slightly smaller,

that rotates in front of it. At the back side of the fixed disk

are pasted two paper inductors with the shape of curved strips

covering an angle of about 90 degrees. These inductors are

connected to "appropriating brushes" that touch

metallic buttons in the rotating disk, as they start to cross the

region over the corresponding inductors. At the angle

corresponding to the other end of the inductors, a neutralizer

bar is positioned in front of the rotating disk. The bar has

brushes that touch the buttons in the rotating disk, surrounded

by combs with points, to act also on the rotating disk surface.

The output is taken by combs positioned horizontally in front of

the rotating disk, opposite to the inductors in the fixed disk (schematic). The design includes also

metallic strips under the paper inductors, terminated in two

disks, one in front of the corresponding appropriating brush,

connected to it by another strip, and other close to the other

end of the inductor (as here [18]). They turn the operation of the

machine less sensitive to the conductivity of the paper, that may

vary with the humidity level. The machine can be seen as a Holtz

machine, with the inductors charged from the buttons in the

rotating disk instead of from the back of the rotating disk, that

is not used, as in a Toepler machine, and with a set of round

metallic sectors that act as a starter for the machine, also as

in a Toepler machine.

The Voss machine, invented in 1880, is

a derivation of the Holtz and Toepler machines (1865), and so is also

known as the Toepler-Holtz machine (or even Toepler-Voss machine,

as Toepler also developed a similar machine by that time). This

design was very popular by the end of that century, being

extensively used for laboratory and medical applications,

including use as power supply for early X-Ray machines. It

consists of a fixed disk and a rotating disk, slightly smaller,

that rotates in front of it. At the back side of the fixed disk

are pasted two paper inductors with the shape of curved strips

covering an angle of about 90 degrees. These inductors are

connected to "appropriating brushes" that touch

metallic buttons in the rotating disk, as they start to cross the

region over the corresponding inductors. At the angle

corresponding to the other end of the inductors, a neutralizer

bar is positioned in front of the rotating disk. The bar has

brushes that touch the buttons in the rotating disk, surrounded

by combs with points, to act also on the rotating disk surface.

The output is taken by combs positioned horizontally in front of

the rotating disk, opposite to the inductors in the fixed disk (schematic). The design includes also

metallic strips under the paper inductors, terminated in two

disks, one in front of the corresponding appropriating brush,

connected to it by another strip, and other close to the other

end of the inductor (as here [18]). They turn the operation of the

machine less sensitive to the conductivity of the paper, that may

vary with the humidity level. The machine can be seen as a Holtz

machine, with the inductors charged from the buttons in the

rotating disk instead of from the back of the rotating disk, that

is not used, as in a Toepler machine, and with a set of round

metallic sectors that act as a starter for the machine, also as

in a Toepler machine.

In June 1998 I completed a double Voss

machine. The machine has two of the basic machines connected

back-to-back, for greater output current and shielding of the

inductors, with shared driving system and terminals. It has a

wood support made of four bars with a cylindric upright support.

The two fixed acrylic disks have 30 cm of diameter, and are

supported by two acrylic pieces below and one above. They can be

rotated to any position, and their separation is of 5 mm. Each

has a set of two inductors, covering angles of 90 degrees and 5

cm wide, made of drawing paper, covering conventional metallic

strips and disks made of aluminum foil. The two rotating acrylic

disks have 27 cm of diameter and are mounted in a single wood

boss, screwed one at each side of a ring, part of the boss

between them, with three screws each. They turn at 2 mm of the

corresponding fixed disks. The boss has ball bearings fixed in

cavities at each extremity, that turn over a steel axis fixed to

the upright support. Each rotating disk has six round sectors

glued to it, with a button stamped in the middle, made of 0.4 mm

aluminum sheet. The neutralizers are fixed to the central axis,

so they can be rotated to any angle, and made with 9 mm aluminum

tubes, 1/8" brass bars that interconnect the combs/brushes

in the two basic machines, 1/16" brass wires for the comb

points, and brass pieces and screws to adapt the tubes to the

brass bars. The brushes were initially made of nickel-chrome

wire, but soon replaced by conductive rubber, that doesn't brake

easily with the repetitive contact with the buttons in the

sectors (the only problem is some startup difficulty in humid

days, comparing to the instantaneous startup with metal brushes).

The brushes are mounted at the end of screws that cross the

aluminum tubes, fixed to holes at their tips with wood pins and

glue, to allow some distance adjustment. The comb points are

simply glued to holes in the aluminum tubes. The charge

collectors and appropriating brushes are of similar construction.

All the extremities of the assembly are covered with 1 cm plastic

beads, or larger wood balls. The terminals are supported by

varnished 1.5 cm PVC tubes. Aluminum tubes connect the charge

collectors to the terminals, passing through wood balls mounted

over the insulating supports and fixed by screws from above. The

spark gap assemblies are connected to these tubes by slotted

brass plugs fixed to wood balls, so they can rotate with some

resistance. The spark gap rods are aluminum tubes that cross that

balls, and make contact with the plugs trough small springs

inside the wood balls. The terminal handles are also 1.5 cm PVC

tubes, adapted to the end of the tubes by nylon pieces, and the

terminal balls are in solid aluminum, turned on the lathe. The

machine is turned by a single pulley connected to a crank,

mounted in a support at the back side. All the wood parts are

varnished with several layers of polyurethane varnish.

My machine can be seen in these ray-tracing drawings, in front view, back

view, and side view. Pictures from

the machine, as initially built are here

(front) and here (back). The final

machine is seen here, with Leyden jars.

A picture of it used to excite my Bonetti

machine by placing one of the terminals in front of a

neutralizer, is shown here (this

single-point excitation works well only in dry air).

A similar, but maybe more beautiful, machine can be seen here [17] (with

the back fixed disk at a strange position). The configuration is

more clearly seen in this quadruple

machine [17].

The machine self-excites easily, and in dry air produces

easily 6 cm sparks between 2.2 cm terminal balls, going to 9-10.5

cm with the addition of a smaller (9 mm) ball to the positive

terminal, and a pair of Leyden jars. In very dry air (as

conditioned air), even with the normal balls it goes to 10 cm sparks, and produces them easily

even with the disks moving slowly. The short-circuit current

reaches 60 uA with the disks turning at about 700 rpm. The

current is very high for a machine of this size, but the voltage

is just regular. In the dark, it is possible to see significant

leakage from the paper inductors to the bars that interconnect

the two sides of the neutralizer. Due to this, the highest

voltage is obtained with the neutralizer bar moved to a high

angle, somewhat away from the area covered by the inductors. In

this condition the machine takes some time to reach maximum

excitation, while charges spread from the inductors to the

surface of the fixed disks under the neutralizers. I added

plastic tubes enclosing the connections between the two sides,

with small improvement. A different design, without that

interconnection is something to experiment. Other leakage points

are the connections of the appropriating brushes to the

inductors, between pairs of inductors, and to the central boss.

The maximum possible spark length, given by twice the distance

between the active area of the disks and the central boss, would

be 11 cm. The machine shows significant resistance to polarity

reversal. Sometimes it reverts polarity after some time of

operation at high voltage, or if one pair of inductors is

grounded for some time while the rotation speed is reduced, or if

turned backwards for some time. The separation of inductors and

output avoids the polarity reversal at each spark, that happens

with my similar machines mounted with output and inductors

directly connected. The machine is significantly less prone to

reversals than the Holtz or Toepler machines. In dry air it is

even rather difficult to obtain a reversal, and the machine

performs as well as a Wimshurst machine, that does not revert

polarity while in operation.

The construction of the machine could be simplified, as there

is no need of two complete machines. One of the sides could have

a bare disk, no appropriating brushes, and no brushes at the

neutralizers, with the inductors connected to the inductors of

the other side. The complete duplication, however, turns easier

the self-excitation of the machine.

This picture shows an old double Voss

machine that is on display in a museum in Lisbon,

Portugal, that has interesting ideas. Note the assembly of the

appropriating brushes, mounted in supports at the frontal hub and

connected to the inductors by flexible wires. They have combs

covering the outer side of the charge transport area. One of the

output charge collectors is broken, and the output terminals are

missing. The rotating disks were made with a kind of mica

composite, and the inductor plates in glass. View of the cabinet. The machine is not quadruple. The

other set visible is a reflection in the glass. Note that there

are no buttons or brushes in the back disk, and that there are

brushes in the frontal charge collectors (why?). An old advertisement of a very similar machine.

These large machines were common as power supplies for early

X-Ray apparatus.

In July 2002, this apparently original

Voss machine, single, was being autioned at eBay. Another view, that shows details of the

construction, and part of a booklet

about it. The structure is as in this

drawing.

P. Atkinson [44] developed two

versions of the Voss machine. A restored single

machine with his design [US275347] patented in 1883 was auctioned in

eBay in 2000. More views of it. The

other was a double machine as mine, described in great detail in

his 1885 patent [US331754].

Voss machines were commonly used in the early 1900's for demonstrations of lightning rods. They were

characteristically mounted in a transportable box, having

attachments representing a "house" and a

"cloud", sometimes with also a "fence" and an

"animal". The machine in the picture appears to be

Baysdorfer's machine [US827497]

(1906). A single Voss machine is shown in [US700536] (1902). A double Voss machine

appears in [US837178]

(1907). Some pictures of a surviving machine of this type,

slightly damaged, were sent by Pete Windahl: Front view, back

view, with the box removed, and label. Another machine is shown in [US1043040] (1912).

By March 2005 a Voss machine was being auctioned in eBay. Front view, back view,

and detail. Note that the fixed disk

is incorrectly mounted. By the structure, this machine was built

in the 1900's.

Created: June 1998.

Last update: 10 March 2005

Created and maintained by Antonio Carlos M.

de Queiroz

Return to Electrostatic Machines

The Voss machine, invented in 1880, is

a derivation of the Holtz and Toepler machines (1865), and so is also

known as the Toepler-Holtz machine (or even Toepler-Voss machine,

as Toepler also developed a similar machine by that time). This

design was very popular by the end of that century, being

extensively used for laboratory and medical applications,

including use as power supply for early X-Ray machines. It

consists of a fixed disk and a rotating disk, slightly smaller,

that rotates in front of it. At the back side of the fixed disk

are pasted two paper inductors with the shape of curved strips

covering an angle of about 90 degrees. These inductors are

connected to "appropriating brushes" that touch

metallic buttons in the rotating disk, as they start to cross the

region over the corresponding inductors. At the angle

corresponding to the other end of the inductors, a neutralizer

bar is positioned in front of the rotating disk. The bar has

brushes that touch the buttons in the rotating disk, surrounded

by combs with points, to act also on the rotating disk surface.

The output is taken by combs positioned horizontally in front of

the rotating disk, opposite to the inductors in the fixed disk (schematic). The design includes also

metallic strips under the paper inductors, terminated in two

disks, one in front of the corresponding appropriating brush,

connected to it by another strip, and other close to the other

end of the inductor (as here [18]). They turn the operation of the

machine less sensitive to the conductivity of the paper, that may

vary with the humidity level. The machine can be seen as a Holtz

machine, with the inductors charged from the buttons in the

rotating disk instead of from the back of the rotating disk, that

is not used, as in a Toepler machine, and with a set of round

metallic sectors that act as a starter for the machine, also as

in a Toepler machine.

The Voss machine, invented in 1880, is

a derivation of the Holtz and Toepler machines (1865), and so is also

known as the Toepler-Holtz machine (or even Toepler-Voss machine,

as Toepler also developed a similar machine by that time). This

design was very popular by the end of that century, being

extensively used for laboratory and medical applications,

including use as power supply for early X-Ray machines. It

consists of a fixed disk and a rotating disk, slightly smaller,

that rotates in front of it. At the back side of the fixed disk

are pasted two paper inductors with the shape of curved strips

covering an angle of about 90 degrees. These inductors are

connected to "appropriating brushes" that touch

metallic buttons in the rotating disk, as they start to cross the

region over the corresponding inductors. At the angle

corresponding to the other end of the inductors, a neutralizer

bar is positioned in front of the rotating disk. The bar has

brushes that touch the buttons in the rotating disk, surrounded

by combs with points, to act also on the rotating disk surface.

The output is taken by combs positioned horizontally in front of

the rotating disk, opposite to the inductors in the fixed disk (schematic). The design includes also

metallic strips under the paper inductors, terminated in two

disks, one in front of the corresponding appropriating brush,

connected to it by another strip, and other close to the other

end of the inductor (as here [18]). They turn the operation of the

machine less sensitive to the conductivity of the paper, that may

vary with the humidity level. The machine can be seen as a Holtz

machine, with the inductors charged from the buttons in the

rotating disk instead of from the back of the rotating disk, that

is not used, as in a Toepler machine, and with a set of round

metallic sectors that act as a starter for the machine, also as

in a Toepler machine.