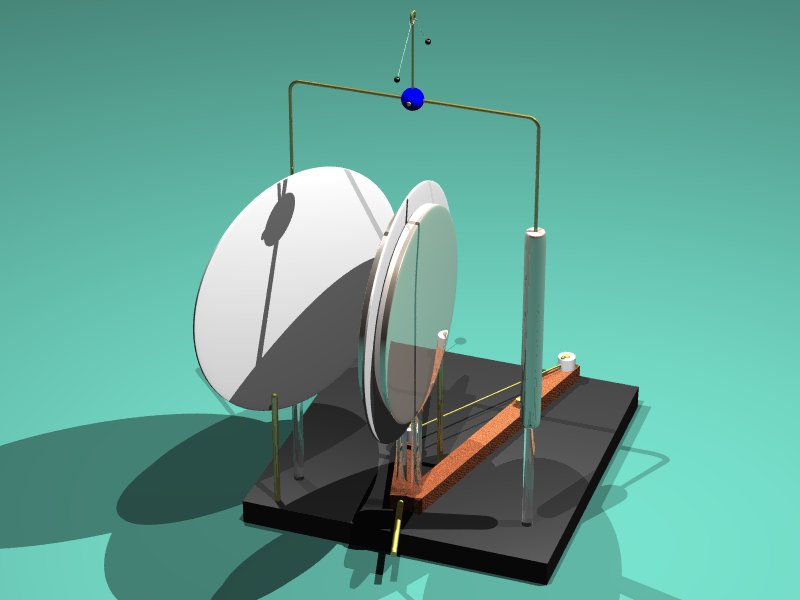

When studying Wilson's

machine I noticed that one of its plates (the rightmost in the

drawing) is just a contact point, and that the central accumulator

plate is not necessary. Without these plates the machine is just a

different version of Bennet's doubler, with

an interesting mechanism. The other mechanical versions of Bennet's

doubler that I had made all moved the disks laterally, what causes

charge accumulation at the sides of the disks and prevents the

achievement of very high voltages, due to sparking caused by the

intense lateral electric fields. A machine built in this way moves the

disks almost along their axles, and should be less sensitive to

excessive charge accumulation at the edges of the disks. This

mechanical construction also differs from the others because there are

no moving contacts. A rotating version of

the same idea resulted in other doubler that I made some time

before, that works quite well. So, by July 2007 I built a version of

this "simplified Wilson's machine". I used three large disks, with 20

cm of diameter, made of plywood covered with aluminum tape, supported

by acrylic rods, and with contact posts and other elements made of

brass. The base was made of plywood, and the levers of wood. I added

also a double ball electrometer in the top connection bar, that serves

as output terminal. With the large disks I was expecting to obtain

visible sparks at the contacts with the machine charged. The machine

has one fixed disk, corresponding to the leftmost disk of Wilson`s

machine, the two movable disks mounted in the reciprocating levers,

and a cylinder replacing the rightmost disk. The gounding posts are as

in Wilson's machine.

The final machine worked as expected

for a Bennet's doubler, self-exciting from discharged plates to full

charge in at most 20 cycles. It clearly works better than my other

mechanical doublers. The mechanical construction is not very practical

at this size, could be more solid, but the machine is still easy to

operate. When fully charged, small sparks can really by seen when the

plates approach the grounding posts and the cylinder, and are clearly

audible. The maximum voltage appears to be something around 20 kV. The

square edges of the plates, the presence of the grounding posts close

to the disks, the electrometer with small balls, and charge

accumulation in the spark shields prevents further increase. I

installed just two spark shields. Maybe better results could be

obtained with the use of pairs of spark shields, one at each plate on

the faces that come close without touching, but this would complicate

the installation of the grounding posts.